| Dura-Belt | 800-770-2358 | WHERE TO BUY | ||

| Next Product |

Elastic, Stretchy Flat Belts (Belting) move heavy loads

WARNING: Increasing hotter summer temperatures can cause stretched flat belts to take a set and lose their elastic memory when they are shipped fully assembled on roller conveyors in hot truck trailers or ocean containers. Therefore, leave the belts unstretched (partially assembly) by not installing the upstream roller until the belts are received in the customer's plant. Also, before assembling flat belts, conveyor frames must be squared with a carpenter's square to prevent flat belts from wandering sideways.

Description

|

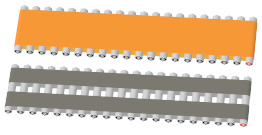

Elastic Stretchy Flat Belting

|

Tracking Sleeves

|

Red Tracking Sleeve under Flat Belt

Note: The actual sleeves are clear not red.

|

Wide Flat Belts on RollersWide elastic flat belts can move heavier loads. They have much more surface contact area than round belts so slipping is virtually eliminated. Low bending loses make them extremely energy efficient. They let you use low powered Motor Driven Rollers (MDRs) or pancake motors to move heavy boxes on longer zones. |

Flat belts move heavier loads

|

|

MDRs do not have thru-shafts like idler rollers, so flat belt tension can bow MDRs, causing them to run on bearing edges and fail prematurely. Therefore, MDRs should be located next to the last downstream roller and power the downstream roller with two HEHT round belts, two poly-v belts or a short flat belt.

Elastic flat belts do not need belt tensioners or V-guides. Instead, tracking sleeves crown the rollers, making our flat belts track so they do not wonder sideways. However, rollers must be 90° perpendicular to the frames, using a carpender square. The adjacent picture shows the most common way to locate four 1" wide tracking sleeves. Sleeves on the downstream roller must be aligned with those on the upstream roller. Instead of using 4 small tracking sleeves, you can use two extra wide tracking sleeves to make installation easier. |

Four 1" wide orange tracking sleeves

|

Flat Belts Increase MDR Zone LengthRound belts usually limit MDR zone length because the belt's thin area of roller contact limits the amount of torque that can be transferred before round belts begin to slip. Wide urethane flat belts do not have this limitation, so slipping is virtually eliminated. Therefore, zone lengths of 20 or more rollers are possible. In fact, except for extremely heavy boxes, the only thing that limits zone length is the torque of the motorized roller. Since our wide flat belts are elastic, they do not need expensive belt tensioners or V-guides, so they can be retrofitted onto conveyors without changing rollers. However, like all flat belts, they will sag underneath rollers, so you may need to add rollers under the conveyor to prevent the belts from rubbing on cross-supports. Our flat belts are more economical than our Poly-V® multi-ribbed belts because they do not need our poly-v endcaps. However, our poly-v belts are better at moving extremely heavy loads, even pallets, at very high speeds. |

Flat belts on long motorized roller zones

(20 rollers or more) Due to larger mass, wide flat belts are stretched much less than round belts. For example, our 1/16" (1.6mm) thick x 4" (100mm) wide belts are typically stretched 3.3%. Please use our belt tension calculator to determine acceptable tension and stretch for your width and thickness |

V-Guides on Flat beltsAs an alternative to crowned rollers and tracking sleeves, Dura-Belt offers V-guides fused to the bottom of our elastic flat belts. They provide very precise belt tracking and eliminate the tiny bumps in the upstream and downstream rollers produced by tracking sleeves. They may also work better in oily or greasy environments where flat belts experience side forces that may dislodge tracking sleeves. Our K6 size V-Guides are available in 80A and 60A durometer, which is softer than our flat belts, so they bend easily around rollers and do not interfere with the flat belt stretch or cause puckering. They fit nicely into standard round grooves in 1.9" or 50mm rollers and can be located anywhere along the inside of flat belts. Please provide a drawing showing exactly where you want them located. |

V-Guides on Flat Belts

|

Flat Belts on Inclines/Declines16 Degrees. New matte surfaces on our elastic flat belts shun dust and give them a higher coefficient of friction (COF), even in dusty environments, so they can move boxes and paper bubble envelopes on inclines and declines of up to 16 degrees*, 33% greater than our old version. These elastic belts move heavier boxes than most other stretchy belts and require no expensive belt tensioners or V-guides. Probably the lowest cost wide flat belts, seventeen miles of these new inexpensive belts are in major distribution warehouses and have been moving 60 lb. (27 kg) boxes up 16° inclines for over four years. They probably can move heavier boxes on the same incline or decline, but customers would need to test it first. Proven quality, our flat belts have been serving customers for over 30 years.45 degrees. With 7/32" tall orange cleats fused to our belts, boxes can move on inclines and declines of up to 45° as in the adjacent picture. Incline Angle Calculate: To find the incline/decline angle of an inclined conveyor, plus a box tumbling (tip-over) calculator to determine the maximum incline angle, click on FAQ 62. |

New surfaces on our stretchy flat belts

move boxes up 16° inclines, 33% higher

Flat belts with orange cleats move boxes

on inclines/declines of up to 45 degrees |

Flat belts much wider than long

Some flat belt experts will tell you that flat belts need to be longer than they are wide in order to track properly (not walk sideways). Dura-Belt's elastic flat belts are the exception. Our flat belting will track regardless of the length to width ratio. Adjacent is one that is 34.5" wide on 9" centers. |

Short, wide flat belting

Urethane has a high coefficient of friction on metal

and UHMW slider beds, so the resultant friction, when moving heavy loads, can overheat our belts, cause them to lose their elasticity and fail prematurely. |

*Note that different container surfaces may behave differently on any flat belt surface. For example, our matte side can convey boxes and paper bubble envelopes on inclines/declines up to 16°, but some types of plastic envelopes may slip. Therefore, you should test your containers carrying different weights on one of our inclined/declined flat belts before purchasing large quantities.