|

Note: To search this page, press Ctrl-F and enter your key word. Eagle XLD O-rings Review

(The search box above will search our whole website.)

Q1 What is the proper way to install elastic belts?

Q1.1 How to determine (calculate) the belt length (i.e., cut length) to order.

Q2 How long do urethane belts last (belt lifespan, shelf-life, life cycle assessment)?

Q3 Why do Cyclothane belts last longer?

Q4 What are Dura-Belt's Terms and Conditions of Sales?

Q5 What effect does high temperature have on urethane belting?

Q6 What effect does low temperature have on urethane belting?

Q7 How can I determine the maximum belt loading tension on a belt?

Q8 What is the difference between Belt Loading Tension and Belt Tension?

Q9 Which size of urethane belt should I use?

Q10 How much should belts be stretched -- stretch factor, stretch percent, stretch amount, pretension belt?

Q11 What's the difference between overlap welds and butt welds?

Q12 Why do overlap welds eventually pull apart under high tension?

Q13 Will our high tension belts damage bearings?

Q14 Do crowns prevent flat belts from moving sideways (walking, wondering), i.e. keep belts centered? Recommended tracking sleeve location.

Q14.1 What causes flat belts to walk or wander? How to stop flat belts from moving sideways.

Q14.2 How to square roller conveyor frames to prevent flat belts from walking (wandering) sideways, or skew rollers gently to move boxes toward one side of a section

Q14.3 What causes flat belts to bunch up longitudinally along the length of the belt? How to fix the bumps.

Q14.4 How to force a flat belt to track (or fine-tune its tracking)

Q15 What is the RAVE technique for tracking sleeve installation?

Q16 How do I prevent tracking sleeves and flat belts from slipping and moving (walking) sideways?

Q17 Where can I get tracking sleeves for small diameter rollers?

Q18 What is our maximum flat belt inclines/declines angle on which boxes can be moved?

Q19 How to easily install stretchy, endless elastic flat belts over rollers?

Q20 Will Dura-Belt's wide-short flat belts track (belts much wider than long)?

Q21 Where do I find Dura-Belt's part numbers?

Q22 How do I clean, sterilize, disinfect, sanitize and/or washdown urethane or Hytrel belts?

Q23 How much should belts wrap around each pulley?

Q24 What is the difference between urethane and polyurethane?

Q25 Do injection molded O-rings make good belts?

Q26 It is rare, but sometimes round belts squeak. What causes it??

Q27 Why do weld joints often protrude slightly in a small bump above the belt's surface?

Q28 How much should right angle diverter belts be stretched?

Q29 How to easily install high tension poly-v HE, HEHT, V-Conform and Hytrel belts without a tool.

Q30 How to size (choose the length) of ConveyXonic Poly-V belts.

Q31 How to make poly-v belts last longer and prevent premature failures.

Q32 What is the shortest Hytrel belt that can be used on 1.9" (48.3mm) conveyor rollers?.

Q33 Can we weld, splice or join Dura-Belt's thermoplastic belts ourselves (Do it yourself)?

Q34 Can Dura-Belt's stretchy, elastic urethane or Hytrel belts be used on slider beds (sliderbeds)?

Q35 How long do Twisted belts (Zero-downtime quick-connect belts) last?

Q36 Thermoplastic urethane belts are NOT precision belts. How are they made? Design tips.

Q37 Why does RPM decline (roller speed slow down) with each slaved roller? -- Creeping vs. Slipping belts

Q38 How to install poly-v and poly-o endcaps on each end of a conveyor roller

Q39 How to clean urethane belts. "Dirty belts" are a positive attribute.

Q40 What causes "shortages" (under-counts) and "overages" (over-counts) in bunches or plastic bags?

Q41 What is the maximum speed for line-shaft and powered roller conveyors using round belts or poly-v belts? (How fast can conveyors move?)

Q42 Are OSHA "pinch point" safety guards required on applications that use Dura-Belt elastic round O-ring belts compared to poly-v belts?

Q43 Do elastic urethane belts stretch and become longer than their original length after they have been installed and run-in for a while?

Q44 Can plastic belts take a set and prevent conveyor rollers from moving at startup, or cause rollers to move slightly backwards or forwards on shutdown?

Q45 Belt slipping problems. What causes belts to slip?

Q46 Are Dura-Belt's belts environmentally friendly, biodegradable, green and recyclable, with a low carbon footprint?

Q47 After installing belts, how soon should you start running them? How long should you let belts sit before running them (run-in time), and how often should you run the conveyor if it is not in use?

Q48 What is the maximum flat belt length?

Q49 Drive motors are usually specified by torque, so why do we use tangential "tension" or "force" instead of "torque" when determining belt tension?

Q50 ConveyXonic Poly-v belts may look ugly compared to competitors' belts. Does that mean ConveyXonic belts have poor quality control (QC) or perform poorly?

Q51 Do reinforced belts stretch? Is a belt tensioner (take up) always needed with reinforced belts?

Q52 Are Eagle XLD O-ring belts as good as they sound?

Q53 What causes split lineshaft spools to come apart?

Q54 Will elastic belts, pre-installed on conveyors and shipped during high daily temperatures in ultra hot containers, lose their elasticity and slip on start up? Can Climate Change (Global Warming) affect elastic belt performance?

Q55 How to install Dura-Belt's Poly-v endcaps on 1.9" 16 gauge steel rollers. Will they slip out of the tube or rotate inside the tube?

Q56 What tools are needed to square a roller conveyor's frame so that flat belts track, i.e., do not walk, wander and move sideways?

Q57 What causes pressed-in Poly-V and Poly-O endcaps (inserts) to crack, split or wobble out of conveyor rollers?

Q58 What Quality Control, Assurance and Inspection Reports (QC Trailer) does Dura-Belt maintain?

Q59 How to stop belts from slipping when oil,grease or other liquids leak on roller conveyors.

Q60 Why are clear color polyurethane belts not always the same clear color (vary in hue)? And will PU's "natural color" affect red, orange, yellow, green, blue, and purple colors?

Q61 How do plastic polyurethane (PU) poly-V belts compare with rubber ConveyXonic poly-V belts?

Q62 How to determine/calculate the incline angle (decline angle) or height of an inclined conveyor. Box tumbling angle (tip over) calculator lets you find the maximum incline angle for your containers.

Q63 Can non-stretch, round, T-top or D shaped belts, usually reinforced with aramid or polyester, replace polyurethane round O-ring belts on roller conveyors powered by Motorized Drive Rollers (MDRs) or the equivalent?

Q1: What is the proper way to install elastic belts?

Here are rules about installing elastic belts:

- Make sure you order rollers with the shaft spring in the grooved end of the roller so you can push the shaft in from the ungrooved end of the roller. If in doubt, order springs on both ends of the roller shaft. It will cost slightly more, but you will be able to push the shaft in from both ends of the roller.

- Always wear eye protection when installing elastic belts. Stretched belts contain a large amount of energy. If belts should break or slip free, they can snap like a whip and put out an eye. This is especially true of hollow belts and twisted belts, which have barbs and hooks on the ends.

- Do not stand in the line of a stretched belt, so that if it breaks and flies free, it will likely not hit you.

- Do not lean backward when stretching belts. If the belt should break or slip, you could fall backward and injure yourself.

- Do not overstretch belts -- not more than 35% beyond the installed length for urethane and 0% for Hytrel polyester. (Hytrel, used primarily in low temperature belts and chemically resistant belts, must never be over stretched even a little because it does not bounce back at all.) Belts stretched beyond their elastic limit will not bounce back as much and will fail prematurely.

- The best way to install endless belts on a conveyor without over stretching them is to touch the rollers together, slide the belt into the grooves, then point the grooved end of the roller to rest on the edge of its frame hole, which will act as the fulcrum of a lever. Now use the ungrooved end of the roller as the handle of that lever, stretching the belts until the grooved end of the shaft pops all the way into its frame hole. Finally, use a putty knife to push the shaft into the ungrooved end of the roller and pop that shaft end into its frame hole. To remove the roller, simply use a screw driver or rod to push the shaft in from the ungrooved end of the roller until it is out of the frame, and use a putty knife to prevent the shaft from scratching the frame. Also watch this round belt replacement video. (Q29 repeats this description for poly-v and high tension belts)

If the roller centers are too close to do this, do not use pliers, a screw driver or a hook to pull the belts over rollers. It can over stress a small section of the cord and cause premature belt failure. Instead, use a metal shoe-horn bent like our shoe-horn tool Round Belt Installer Tool. It greatly facilitates installation and will not over stress the belts.

- If more than 70 lbs of force is required to pull the roller in place, you can use a crowbar or winch. Inexpensive winches can be purchased on-line from Lowe's. However, most people angle the roller in order to insert its shaft in the frame hole closest to the belts; then they use the roller as a lever and insert the shaft's other end in the frame.

- If you have two fixed pulleys, put the belt on the larger one and roll it on the smaller one.

- Never use a screw driver, hook, narrow rod, wire or rope to stretch a belt. They will over stress the belt, causing it to bend too sharply, violating its minimum pulley diameter and producing a weak point that will neck down and make the belt fail prematurely.

- The best way to install twisted quick connect belts, without dropping rollers, is to use our Speedy Belt Installer Tool. If you can easily stretch twisted belts over rollers while keeping them in the frame, then the belts are too long and will stop driving prematurely.

Back to top

Q1.1: How determine (calculate) the belt length (i.e., cut length) to order.

Click on Belt Sizer Instructions and follow the instructions there. It will recommend the easiest way to determine the belt's cut length is to follow our Belt Sizer Length Calculator Method 2 instructions.

If you are unsure about what belt tension to use, then click on our Belt Sizer Tension Calculator to determine the percent stretch you want. You may have to try several different stretches before you find the tension you need.

Next remember the percent stretch, and go to Belt Sizer Length Calculator Method3 to determine the belt cut length to order.

Initially, order just one belt to make sure it fits correctly, If it does, then you can order larger quantities with assurance they will fit correctly.

To switch back and forth between the Length Calculator and Tension Calculator pages, click on "Next Calc" at the top right of the pages. Sometimes you need to click it twice to jump over the Belt Cross-Section Calculator page.

Back to top

Q2: How long do urethane belts last (lifespan, shelf-life, life cycle assessment)?

Polyurethane round belts lifespan can vary widely, depending upon how they are used or abused. We rarely get feedback on our belt lifespan so their lifespan is probably acceptable to most users, although everyone would like their belts to last longer and ask for life cycle assessments. Here are some examples that may explain why we do not get a lot of feedback:

- Cyclothane-A and -B. our most common ester-based polyurethane (PU) belts, have a shelf life that can be extended to 12 years or more by storing them is a cool, dark, dry place. However, their shelf-life is adversely affected by higher temperatures, UV and high humidity. Ester-based PU is hygroscopic so it can absorb water vapor out of the air. Therefore, we store our inventory at less than 72°F (22°C), in sealed boxes at less than 50% relative humidity.

Cyclothane-E is ether-based PU that is water resistant and has UV blocking additives so it resists high humidity and will last twice as long as ester-based PU in water at 100°F (38°C), but we still keep it in a cool, dark, dry place.

- We warrant our belts with our World's Longest Belt Warranty against breakage at the weld for 10 years or the life of the belt whichever is longer. Our warranty expense is less than $300 per year so weld breakage has never been a problem.

- Twenty-eight years ago in a real world test at the USPS postal distribution center in Charlotte NC in an ideal temperature and humidity controlled environment with precision rollers (TIR 0.015"), nearly all of our 40,000 HT (High Tension) Blue Cyclothane-B belts were still running strong after 9 years. This was verified by our visit to their center. The test was terminated by the USPS when they split up and moved their conveyors to many different locations so our belts probably lasted longer, but we could not longer track them.

- An engineer, who has recommended our belts for over 20 years, says his largest customer has applications where our round belts are still running after 13 years.

- Ermanco started using polyurethane round belts in the sixties. They are now owned by Fortna, one of the largest conveyor manufacturers. They offer a 5 year warranty on our "Xeno" belts and have purchased millions over the past 32 years.

- Motorized roller belts usually last longer than lineshaft belts because lineshaft belts travel in two different planes 90° apart so they rub against roller grooves and spools at an angle, causing them to abrade slowly over time. Whereas, MDR belts on straight conveyor sections only move in one plane, so they do not rub against grooves and do not abrade, unless they are abused and forced to slip.

There are many factors that determine the life-span of a belt, including operating schedule (shifts per week), duty cycle, belt type, belt length, belt thickness, belt durometer, belt stretch, belt speed, pulley or roller size, pulley or roller material, pulley alignment (angle between pulleys), bearing type (sealed vs. shielded), ambient temperature and humidity, amount and type of dust and dirt in the environment, chemical and UV exposure, box weight, box surface, amount of box accumulation (duration and frequency), motor acceleration/deceleration, conveyor type, conveyor design, conveyor width, level of maintenance, and abuse. (Also see Longer Lasting Belts, What kinds of abuse can cause belts to fail prematurely). If your belts are wearing out too soon, ask our Belt Doctor for assistance.

Back to top

Q3: Why do Cyclothane belts last longer?

Several factors combine to make Cyclothane belts last longer:

- We use only 100% virgin polyurethane (no regrind waste). Urethane manufacturers typically recommend using up to 25% regrind waste to improve extrudability and weldability, plus it cut costs by reusing waste. Unfortunately, regrind picks up impurities like dust and has an extra heat cycle that weakens the material and makes belts less resilient, so we don't use it, even though we believe virtually everyone else does. We send our waste to a tube manufacturer. Virgin urethane makes our belts stronger and last longer.

- Our proprietary process for making Super Strong Welds that are practicably unbreakable -- up to 12 times stronger than conventional joining processes.

- Our ungouged welds do not neck down much when stretched. Necked belts stretch more at the joint which causes them to get limp prematurely.

- Our proprietary process for cross-linking long-chain molecules makes our HT belts super resilient at 20% stretch.

- Our proprietary coloring process lets us color belts after we make them, so that the colorant does not dilute or weaken the urethane.

- Our superior quality control process -- we inspect 102% of our belts (2% are inspected twice). Compliant with ISO 9000, we constantly strive for improvements.

- Our World's Longest Belt Warranty induces us to make doubly sure that we ship only high quality belt.

- Our "Belt Doctor" helps customers find and eliminate problems that cause belts to fail prematurely.

Back to top

Q4: What are Dura-Belt's Terms and Conditions of Sales?

To see them click here

Back to top

Q5: What effect does high temperature have on urethane belting?

Most urethane that is used in elastic belting is a thermoplastic, so its physical properties decrease as temperature rises. For example, at 120oF (49oC.) its life span as measured by resiliency declines to about 70% of what it is at room temperature; at 150oF (66oC) its resiliency drops to about 10%. Some manufacturers claim that urethane will work continuously up to 180oF (82oC.), but that is only when urethane O-rings are used as seals under compression. Belts under extension will only last a short time at that temperature. In some applications they may seem to last longer because the temperature underneath the rollers is much lower. In such cases, you need to average the temperature on top of the rollers with that underneath the rollers to get the actual operation temperature. It is for these reasons that we are more conservative and recommend a maximum operating temperature of 130oF (55oC.).

If you need elastic, high temperature belts, try our High Temperature Urethane Belts. They will work up to 230oF (110oC), but they are much more expensive and only come in certain sizes. ThermoSET urethane will also work at higher temperatures, but it has to be molded or cast, so only certain sizes are available, and the molds are expensive. Its elastic memory is often poor, so it usually does not make a good elastic belt.

Back to top.

Q6: What effect does low temperature have on urethane belting?

Urethane becomes more brittle as temperature decreases. Belts that are allowed to sit overnight in low temperature environments can take a set that is difficult to overcome at start up. This can cause even Super Strong welds to shear apart. Although urethane manufacturers often claim that regular urethane will work down to -10°F, we do not recommend using Cyclothane-A below 28°F (-2°C). Our low temperature Cyclothane-E will work down to 15°F (-9°C), but for temperatures below 15°F (-9°C) we recommend Hytrel ®. It will work down to -40°F (-40°C) and is especially well suited for ice cream plants and sushi warehouses. Since Hytrel is not as resilient as urethane, it should not be stretched beyond 7%. Care must be taken not to overstretch it during installation because Hytrel will not bounce back if overstretched.

Back to top

Q7: How can I determine the maximum belt loading tension on a belt?

See instructions under the BELT SIZER pull down menu.

Back to top

Q8: What is the difference between Belt Loading Tension and Belt Tension?

Some companies define belt loading tension and belt tension differently. Here is how we do it:

Belt Loading Tension is the maximum tangential force that the belt needs to exert in order to turn the driven pulley.

Belt Tension is displayed on our tension calculator. It must be greater than the belt loading tension. Otherwise, the belt will not turn the driven pulley. Ideally belt tension should be 3 times or more than the belt loading tension in order to maximize the belt's lifespan.

Our numbers are conservative, so users sometimes accept a shorter lifespan by using belt tension that is closer to the belt loading tension so they can move heavier loads with a thinner belt.

Back to top

Q9: Which size of urethane belt should I use?

See instructions under the BELT SIZER pull down menu.

Back to top

Q10: How much should belts be stretched -- stretch factor, stretch percent, stretch amount, , pretension belt?

For a list of typical round and V-belt stretch factors, click here. The stretch on flat belts varies with thickness and width. For the recommended stretch on flat belts, click here.

Back to top

Q11: What's the difference between overlap welds and butt welds on reinforced urethane belts?

You can easily see the difference between an overlap weld and a butt weld. An overlap weld usually has a big 2" long bump at the joint where the reinforcing cords are overlapped, whereas a butt weld is just a thin line circling the belt. Overlap splices can last a little longer than butt welds if they are perfectly made, but it is hard to make perfect overlaps. A thick layer of urethane must surround each cord. If the two cords touch each other, or if one cord is too close to the surface, the cord pulls out and the belt stretches prematurely. Trying to make perfect overlap welds often produces quite a few rejects, so the price must be higher than for butt welds. (see next question).

Back to top

Q12: Why do overlap welds eventually pull apart in high tension applications?

Since the reinforced cord is not endless or tied, high tension applications will eventually cause the reinforcement to disbond and slide through the urethane.

Back to top

Q13: Will our high tension belts damage bearings?

No, because most bearings will take loads considerably larger than our belts can exert. For example, our 3/16" HT Blue belt exerts an initial force of about 25 lbs (12kg), but typical 1.9" (50mm) diameter conveyor rollers will handle a maximum load of 250 lbs (100kg), which is 10 times larger. Moreover, urethane belt tension declines quickly at first. Five minutes after installation, it drops 30%, and after a week the tension levels off at about 14 lbs (30kg). Our idler pulleys use the 6203 bearing, rated at 600 lbs (270 kg) at typical conveyor speeds, so the chances of bearing damage are slim or none. Nevertheless, make sure that your belt tension does not exceed the rating of your application. Our tension calculator lets you calculate the force exerted by our belts.

Back to top

Q14: Do crowns prevent flat belts from moving sideways (walking, wondering), i.e. keep belts centered? Recommended tracking sleeve location, and what to do if a flat belt does not track, i.e. walks or wanders?

Yes, a crown on a pulley will prevent "walking or wandering". All flat belts have a tendency to "walk", "wander" or move sideways on flat surfaces. Therefore, uncrowned, flanged pulleys are not recommended because the belt will either rub against the flange and abrade, or stretch and walk up over the flanges. To hold the belt in the center of the pulley, the pulley must be crowned, i.e., larger at the center than on the sides. (See drawing below). All our flat idler pulleys have round crowns of .016" to .020" See crowns on flat idler pulleys. This means that the center diameters are .032" to .040" greater than the diameters at the outside edges of the pulleys.

Flat Belt Pulley Crowns

Flat belts on conveyor rollers. Our tracking sleeves provide a quick way to add a rectangular crown to rollers. For narrow elastic belts, up to 2" (50mm) wide, use 1/32" (0.8mm) thick sleeves 92A durometer. For wider belts use 1/16" (1.6mm) thick sleeves 83A durometer. Our standard 1/32" (0.8mm) thick x 1/2" (12.5mm) wide tracking sleeve is stretched 10%, as is our 1/16" x 1" tracking sleeve.

One customer uses 2" long standard 1.9" roller covers as tracking sleeves. However, they should be longer than 2" because 2" ones have been known to walk, so for short 2" ones you should also use an adhesive, e.g., put a dab of contact cement under the edges located at 90° intervals.wide tracking sleeves See Q16 below. Also see Extra wWide tracking sleeves

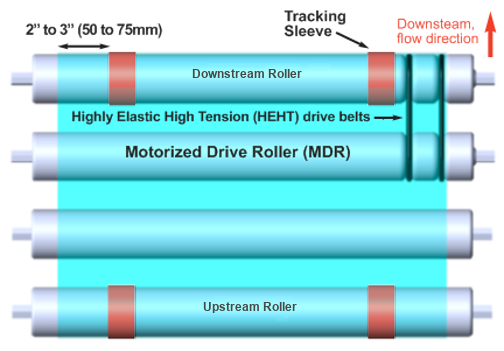

Most conveyor manufactures use tracking sleeves on both the downstream and upstream rollers as in the picture below. They do this because they cannot be sure that their frames are always square (sometimes due to a forklift bumping a conveyor) and/or because there may be side forces on the belts as when boxes are pushed on from the sides. Moreover, no belt is perfectly square so sleeves on both downstream and upstream rollers are highly recommended unless you use an ultra-wide thacking sleeve.

Sleeves on the downstream roller should be aligned to the sleeves on the upstream roller within +/-1/16" so they do not fight each other.

We recommend the following:

- Narrow flat belts up to 2" (50mm) wide - use a 1/32" thick x 1/2" wide (0.8mm x 12mm) 92A tracking sleeve, located in the middle of the belt on the drive roller. If the center distance between downstream and upstream rollers is small (e.g. 8" or less), this is the only case where only one tracking sleeve is needed. For longer center distances use a tracking sleeve on both rollers.

- Medium wide flat belts up to 9" (230mm) wide -- use a 1/16" thick x 1" wide (1.6mm x 25.4mm) 83A tracking sleeves, located in the middle of the belt on both the downstream and upstream rollers.

- Flat belts above 9" (230mm) wide - it is better to simulate wide crowns by using two 1/16" thick x 1" on both the lead and tail rollers. Locate the outside edge of the tracking sleeves 2" (50mm) from the edges of the flat belt.

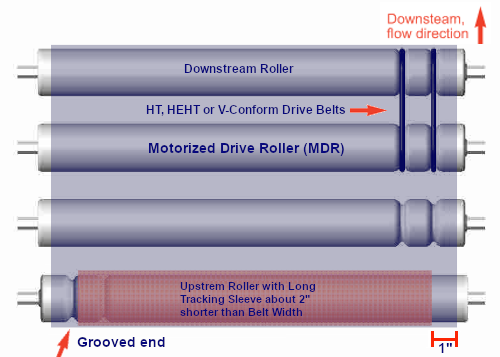

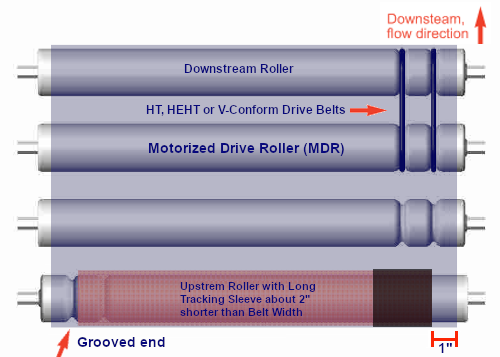

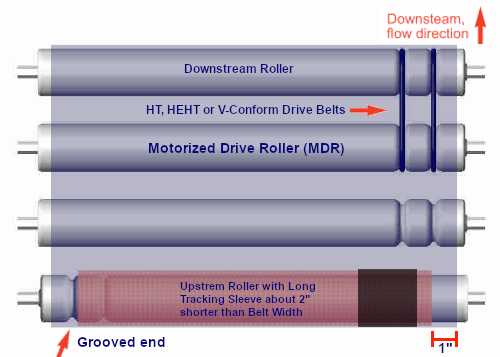

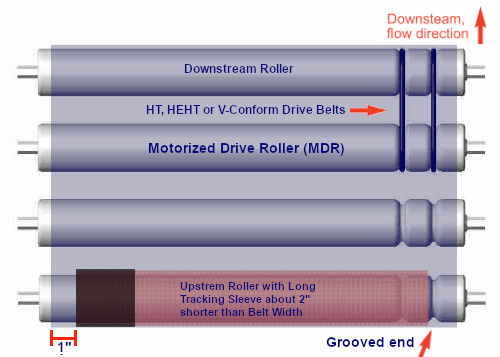

- Motorized Drive Rollers (MDRs) do not have thru-shafts so they are not nearly as strong as standard rollers. Wide flat belt focus pressure on the center of MDRs where they are weak. This slightly bows MDRs causing their bearings to ride on their edges, which can cause premature MDR failure. Therefore, we recommend locating the MDR in the position shown below and driving the roller with two 88A HEHT round belts, V-Conform belts or poly-v belts. The ends of MDRs are much stronger and can easily handle the tension of round, V-Conform or poly-v belts.

Tracking sleeves on wide flat belt conveyor

(Available on any size roller. Use screw driver technique to install.)

Many conveyor manufacturers position four tracking sleeve as in the picture above, but sometimes the tracking sleevs themselves can move, especially if the rollers have not bee cleaned before installing sleeves. To further prevent sleeves from moving an adheasive is often used (see Rave).

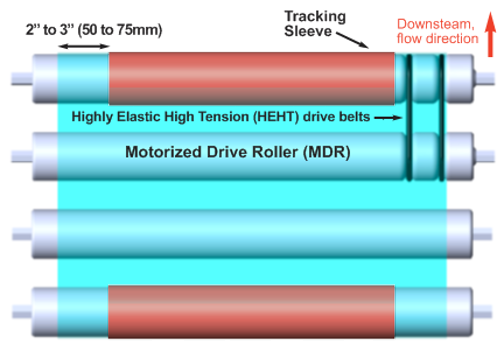

To ensure sleeves do not move other manufacturer uses extra-wide sleeves like this.

Wide lagging tracking sleeves on wide flat belt conveyor

(Available on 1.9" and 50mm rollers. Use Sleeve Installer to install.)

We discovered a new, easier way to force flat belts to track perfectly. Simply install a single, ultra-long tracking sleeve on the upstream roller. It's the easiest roller to remove and modify as compared to installing the standard four smaller tracking sleeves on two rollers. Moreover, the ultra-long sleeve has so much surface contact with its roller that it should not walk no matter how much side pressure is exerted on it.

Use the Sleeve Installer to install it. For detailed step-by-step instructions to force any flat belt to track see Q14.4.

How to force a flat belt to track with just the upstream roller

(See step-by-step instructions at Q14.4.)

Back to top

Q14.1: What causes flat belts to walk or wander? How to stop flat belts from moving sideways.

Flat belts walk if conveyor is not level

Square, skewed and misaligned rollers Flat belt walking on skewed frame

If the conveyor is not level and/or the rollers are not square to the frame, flat belts will move to one side and sometimes drag the tracking sleeves with them.

The rollers may look exactly like they are square to the frame, but you will not know for sure unless you use a square to verify that the downstream and upstream rollers are angled at precisely 90 degrees with respect to the frames. If they are not, then square the frames and rollers using a large carpenter square. See Q56.

Next verify that the tracking sleeves are located, as in the above drawing, so they do not fight each other (i.e., so that sleeve edges are aligned precisely on a line from the downstream and upstream rollers).

If the belt still walks, you can force it to track by going to Q14.4. Or you can go to the next paragraph to determine if your rollers are perpendicular to the frames

Place a piece of masking tape on the right edge of the belt; otherwise you will forget which side was on the right (this is absolutely CRITICAL). Next remove the belt and verify that all tracking sleeves are in the correct location and proceed to the next paragraph. If sleeves are not where they should be, take corrective action, see Q16.

If all the sleeves are located where they should be, then reverse the belt on the conveyor so the masking tape is on left edge of the belt. If the belt walks in the same direction, then the frames are not square and/or the rollers are not parallel, and you will need to take more action to square the rollers to the frames using a large carpenter square. See Q56. If the belt walks in the opposite direction, then any number of things may cause the belt to not track (i.e., the belt may not be perfectly square, it might be slightly curved, internal stresses may cause it to track unevenly, or the thickness may vary from edge to edge). Therefore, go to Q14.4.

Back to top

Q14.2: How to square roller conveyor frames to prevent flat belts from walking (wandering) sideways, or skew rollers gently to move boxes toward one side of a section.

Rollers may appear to be absolutely perpendicular to the frames as seen by your eye, but they can still be off by a few degrees. To square a conveyor section, you should use a large carpenter square to ensure the rollers are accurately aligned perpendicular to the frame.

Where frames and cross-struts are not welded, it is usually easier to square or skew roller frames by loosening the leg bolts on one side of a section and taping the frame to square or skew the rollers.

Another way to gently square or skew rollers is to use turnbuckles. Click here to see how that is done.

href="https://www.durabelt.com/downloads/pdf/Turnbuckle_X_skewing_or_correcting_un-square_rollers_X.pdf" target="_blank

Neither of the above methods may work on conveyor sections if your cross-struts are welded to frames. Then the only way to square them is to cut and re-weld the struts after the rollers have been squared. That is not practical so go to Q14.4

href="https://www.durabelt.com/downloads/pdf/Turnbuckle_X_skewing_or_correcting_un-square_rollers_X.pdf" target="_blank

Neither of the above methods may work on conveyor sections if your cross-struts are welded to frames. Then the only way to square them is to cut and re-weld the struts after the rollers have been squared. That is not practical so go to Q14.4

Back to top

Q14.3: What causes flat belts to bunch up longitudinally along the length of the belt? How to fix long bumps.

Flat belts bunching up

Flat belts bunching up

This picture shows flat belts bunching up longitudinally along the length of the belt.

Misaligned tracking sleeves

Misaligned tracking sleeves

This can be caused when wide lagging tracking sleeves are misaligned like this drawing.

The solution is to re-align the lagging tracking sleeves so they do not fight each other.

Alternately, remove one wide tracking sleeve because one alone is usually all that is needed to force the belt to track.

Moreover, since tracking sleeves are made from a static insulating plastic material, eliminating one will reduce much of the flat belt's static electric charge by letting it wrap half way around a grounded steel roller

Back to top

Q14.4: How to force a flat belt to track (or fine-tune its tracking).

If your conveyor has screw or cam adjusters that tilt the downstream roller, use them to make the flat belts track, i.e,, center them on your rollers.

If you have turn-buckles under your conveyor zones with crossed wires attached to opposite frame corners, tighten or loosen those to warp the zone to force flat belts to track.

The following steps apply to our drawings below as well as the other drawings of tracking sleeve locations in Q14. However, the black tape will have the most dramatic effect on the extra-long tracking sleeve below because it will be located closest to the belt edge.

-

Roller grooves can effect flat belt tracking, so if a flat belt does not track, the first thing to do is flip the upstream roller so its grooves are close to the opposite frame like the first drawing below. If this causes the belt to track in the center of the roller, then stop here.

- If the flat belt tracks to the left, make sure the grooved end of the upstream roller is on the left, then place a single layer of tape (e,g,, black Gorilla* tape 6.25" long on 1.9" rollers) around the right edge of the tracking sleeve.

If belt tracks left, put tape around right end of tracking sleeve

- If the belt still tracks to the left, then place another layer of tape on top of the layer. Keep adding single layers of tape until the belt tracks.

- If the belt tracks too far to the right, move the tape slightly to the left (e.g.,in half inch increments). You can move the tape back-and-forth to fine-tune tracking.

If belt tracks too far right, move tape slightly to the left

- If the flat belt initially tracks to the right, make sure the grooved end of the upstream roller is on the right, then place a single layer of tape (e,g,, black Gorilla* tape 6.25" long on 1.9" rollers) around the left edge of the tracking sleeve, and continue as in steps 2 through 4 above.

If belt tracks right, put tape around left end of tracking sleeve

*We have tested Gorilla Tape for only a few months. It seems to work well and does not debond, but still can be easily repositioned. Nevertheless, there may be other tapes that work longer, so you may wish to test others. Kindly inform us if you find a better one.

Back to top

Q15: What is the RAVE technique for tracking sleeve installation?

Before installing tracking sleeves, clean the rollers with acetone or alcohol to remove any oil or grease that may cause the sleeves to walk and wander.

We recommend using RAVE 4X Mega Hold Non-Aerosol Hair Spray Unscented to lubricate tracking sleeves, making them easier to install. It is available on-line. After about 2 minutes, it dries to form a semi-hard coating that acts like a weak glue to help prevent tracking sleeves from walking and wandering.

RAVE comes in a safer non-pressurized plastic bottle, but contains alcohol so it is flammable before it dries, but it appears to be safer than the aerosol can version that produces a mist that is easier to ignite and inhale. RAVE should be used in a well ventilated area. If you are installing many sleeves, wear an activated-carbon mask to prevent inhaling fumes.

DO NOT USE ANY SPRAY THAT COMES IN A METAL CAN. IT IS UNDER PRESSURE SO IT CAN EXPLODE AND USUALLY CONTAINS A GAS AND LIQUIDS THAT ARE EXTREMELY FLAMMABLE.

Do NOT use lubricants or soapy water. After they dry, they still are slippery so they can cause sleeves to walk and wonder.

Do NOT use brake cleaner because it contains many toxic, flammable chemicals that attack and weaken urethane as well as injure humans because they are dangerous to inhale and can be absorbed through the skin.

There are several different ways to install tracking sleeves along a roller lubricated with RAVE hair spray. Some companies machine a split shaft collar so its ID is a slip fit over the roller and tug on it to pull the tracking sleeve to the desire location. Some use 2" OD Schedule 80 PVC pipe that has a 1.9" ID to push the sleeve along the roller. Some use two strings looped through the sleeve 180 degrees apart to pull them on. Others build a finger-like stretcher to hold them open while they slide the rollers through. The following screw driver technique is the most popular, while the tools below greatly facilitate installation.

Some conveyor manufacturers use 2" wide tracking sleeves that we sell, but they are not as tight as our 1" wide ones, so they walk more easily. Therefore, we recommend you use RAVE plus the contact cement described in the next Q16.

Screw Driver Technique: Here is a way to install narrow sleeves (1.18" wide or less). It may appear that the sleeve is too small to fit on the roller, but it can be done with some effort. Push the sleeve a tiny way on the roller end. Then insert a small screw driver (e.g. with 1/8" shaft) at an angle between the sleeve and the roller. Be careful not to spear your hand with the screw driver. Now rotate the roller in the direction of the red arrow to screw on the sleeve. The screw driver makes it seem like there are threads on the roller and causes the sleeve to screw on like a nut. It works exceptionally fast when installing on an MDR because you can turn on the MDR and the sleeve will screw its way down the MDR.

One inch wide tracking sleeve installed with screw driver

Tracking Sleeve Installer Tools. Over the last 30 years we have sold millions of tight 1/16" x 1" x 5.59" tracking sleeves that were designed by our customers, but we have always wondered how customers installed them easily. Even when we followed their instructions on our web page, we found it very difficult and time consuming.

The toughest part is getting our tight sleeve's 1.71" ID on the 1.9" OD roller, but that is made much easier with the tools below. First, load one end of the roller a few inches deep into a lathe that is set to rotate at an extremely slow speed -- like one revolution every 4 seconds. Next, using water to lubricate the sleeve, cone and roller end, use the lathe's tailstock to push the sleeve on the roller by applying pressure against the 4-fingered pusher device. (Steps 1 through 3 below).

Tracking Sleeve Installer Tools

Now remove the cone and 4-finger pusher, insert a thin screw driver under the sleeve and turn on the lathe, using the Screw Driver Technique to screw the sleeve to its final position on the roller.

Alternately, on 1.9" diameter rollers, you can use RAVE hair spray and 80 Schedule PVC pipe (blue tube in steps 4 and 5) to push the tracking sleeve into final position.

Since there has been little demand for the tool, we do not sell it, but we will provide rough drawings on demand so you can construct it yourself. The cone is machined from Delrin, and the 4-finger pusher is made from aluminum.

Back to top

Q16: How do I prevent tracking sleeves and flat belts from slipping and moving sideways?

Before reading any further, go to FAQ14.1Q14.1 and see what causes tracking sleeves (that should not move) to break loose and walk or wander sideways.

Then do the following to make it extra difficult for tracking sleeves to move:

- Rollers are often covered with a thin coat of oil (e.g. cutting fluid) or grease to prevent rust. This can cause sleeves to slip sideways when side pressure is put on the belts. Before installing sleeves, wipe rollers with acetone or alcohol to remove any oil or grease.

- Some conveyed products like tires tend to rotate when they rub against conveyor frames. This rotation puts side forces on flat belts and tracking sleeves that may push them to walk sideways. Therefore, we recommend using narrow flat belts separated by roller sleeves that are thicker than the flat belts plus tracking sleeves. This will prevent the tires from touching the flat belts, and thus eliminate any side forces that might cause them to walk.

- Some installers use two hooks to stretch sleeves over rollers. If sleeves are stretched more than 40%, they may deform because the urethane has been stretched beyond its elastic limit. This will reduce sleeves' holding tension. Therefore, do not overstretch sleeves during installation.

- If a sleeve has already slipped, clean the roller with acetone and move the sleeve back to its original position, using the RAVE technique. Then, after RAVE dries, use a small screw driver to lift the edge of the sleeve while putting a dab of contact cement (e.g. DAP Weldwood) at 0°, 90°, 180°, and 270° around its circumference under both edges. If you use contact cement, you do not have to let each surface dry before bringing the surfaces together. However, let the cement dry for an hour before restarting the conveyor.

- If the sleeve still slips, clean the roller with acetone on each side of the sleeve. Then make a barrier on each side of the sleeve by winding 3 or 4 layers of aluminum foil tape around the roller. (We recommend Nashau aluminum foil tape because its adhesive binds so tightly that it is almost impossible to pull apart. If you want to remove it, you have to cut it off with a razor. The adhesive on 3M aluminum tape seems to become gummy and slip after a while, so do not use it.) If the barrier is about one third as thick as the sleeve, the sleeve will be locked in position.

- If none of this works, then try a tighter sleeve.

- With flat belts wider than 8", use 1/16" thick sleeves 4" to 6" (100mm to 150mm) shorter than the flat belt's width. See drawing at Extra-Wide

Tracking Sleeves. The surface area under such sleeves is so great that they have not been known to walk.

Back to top

Q17: Where can I get tracking sleeves for small diameter rollers?

We cannot weld tracking sleeves for rollers less than 1.5" (38mm) in diameter. If the order is large enough, e.g. 500 pieces or more, we can extrude tubing to make them, but for small orders we recommend making them yourself using self-fusing silicone tape. We sell it in rolls 1" wide x 36 yards long. Before installing tape sleeves, the rollers must be cleaned with alcohol or acetone to remove any oil. Otherwise, the silicone may slip. Stretch the tape about double, i.e., 100%, and tightly wind it around the roller a few times to build up thickness. After five minutes, it will fuse into a solid mass, and you will not be able to unwind it. For use with narrow flat belts, e.g. 1" (25mm) wide, you will need to slit the tape to reduce its width to 1/2" (12mm). This is probably best done with a razor after the tape is wound around the roller.

Tape sleeves will not be as uniform in thickness as urethane sleeves, so your flat belt may wobble at bit. We do not have experience with slipping or lifespan, but installers have been substituting them in field emergencies for years, so they must work for an acceptable time.

Back to top

Q18: What is our maximum flat belt incline/decline angle on which boxes can be moved?

See Flat Belts on Inclines/Declines.

Back to top

Q19: How to easily install stretchy, endless elastic flat belts over rollers?

Because our stretchy, elastic flat belts must be stretched during installation, they may appear difficult to install, but it is much easier than it looks. Simply drop all rollers on one side of the frame. Then slide the flat belt over those rollers while dropping the last roller from both sides of the frame. Install all but the last roller in the frame. The last roller should be hanging inside the belt about an inch from its frame holes. Now grasp the last roller and the belt, insert the roller's shaft at an angle into one frame hole. Then insert a flat screw driver in the opposite frame in the unused adjacent hex hole, i.e., the hole used to skew rollers, usually 1" from the target hole. Now press the screw drive blade against the last roller's edge, using the hole as a fulcrum, and leverage the last roller into the target hole. The hex shaft is perfectly oriented to the hex target hole, so it snaps in quickly with very little effort -- only takes a few seconds. If there are no skew holes, then you would need to drill one. This process greatly facilitates and speeds up assembly.

Back to top

Q20: Will Dura-Belt's wide-short flat belts track (belts much wider than long)?

Most flat belt experts will tell you that flat belts need to be longer than they are wide in order to track properly (not walk sideways). Dura-Belt's elastic flat belts are the exception. Our flat belts will track regardless of the length to width ratio. Here is one that is 34.5" wide on 9" centers.

Wide-short flat belt tracks well

Back to top

Q21: Where do I find Dura-Belt's part numbers?

Theoretically we have an infinite number of part numbers because we can make belts of any length. To date we have over 10,000 part numbers. That is why it is not practical to show them. Just tell us the description and we'll tell you the part number.

Actually all are part numbers are "smart", meaning they describe the belt. The first two digits are the thickness in inches without the decimal point. letter is a code for the durometer (a = 83A, 85A or 88A, r = 90A, 92A or 95A). The next 5 digits are the cut length in inches. The words describe special attributes, like Rough Green, Orange, HT Blue, Super Red, Static Dissipative, etc. No words means it is standard clear urethane.

For example, our popular 3/16" (.187") x 9.5" HT Blue belt's part number is 18a09.50 HT Blue

Back to top

Q22: How do I clean, sterilize, disinfect, sanitize and/or washdown urethane or Hytrel belts?

Food processing plants often disinfect their conveyors by washing down with a 20% bleach solution. Bleach attacks urethane, causing it to crack and lose its elasticity, so bleach should not be used to sanitize urethane belts. Food processors that wash down with bleach should use Hytrel belts. (Make sure Hytrel belts are not overstretched during installation, as Hytrel does not "bounce back" like urethane.)

In our laboratory tests we found that Oxine (Chlorine Dioxide), a biocide disinfectant and sanitizer, has minimal effect on urethane, when used at Kermin's recommended 100 ppm concentration in solution with room temperature water for short exposure times. Moreover, Oxine appears to have virtually no effect on Hytrel belts, even up to 500ppm with prolonged exposure at room temperature.

Urethane belts can also be cleaned by washing them in lukewarm water (120°F, 50°C or less) with dish washing soap like Palmolive or Joy.

Occasional washing of Cyclothane-A urethane will probably not harm the belt, but since it is hygroscopic, frequent washing can slowly damage it, especially if the water is hot. Cyclothane-E belts are not hygroscopic, so frequent washing should not affect them.

Isopropyl alcohol (rubbing alcohol) can be used to clean the surface of urethane, as it evaporates quickly, but prolonged immersion in alcohol will damage urethane.

Steam is not recommended for cleaning any thermoplastic belt because high temperatures reduce belt life. However, steam may cool down substantially by the time it contacts the belts, so flashing them with "cool" steam (150°F, 70°C or less) may not significantly harm Hytrel or Cyclothane-E.

When in doubt, test a few belts before applying any substance to all belts. We recommend immersing a belt in a bottle of the chemical and letting it sit for a week at the belt's operating temperature. If there is any change in the surface or tensile strength, then the chemical is harming the belt.

Back to top

Q23: How much should belts wrap around each pulley?

Most applications are designed so that belts wrap between 120 and 240 degrees around their pulleys. If the force needed to turn a pulley is very small, then you may not need more than 90 degrees of wrap. However, tension in urethane belts declines over time, so what is acceptable today might not work in two years. Therefore, if in doubt, increase the belt wrap as much as possible by moving the pulleys further apart and/or by adding an idler pulley that forces the belts to wrap more about the drive and driven pulleys. The more wrap you have, the less the belt will tend to slip, and the more force will be exerted on the other pulley. If you have enough surface contact (i.e., a lot of wrap), then there may be enough friction between surfaces so that everything continues to work, even after the belt becomes limp.

Back to top

Q24: What is the difference between urethane and polyurethane?

There is no difference. In the belting industry they are synonymous. All urethane belts are made from polyurethane, which contains long-chain urethane molecules.

Back to top

Q25: Do injected molded O-rings make good belts?

Extruded urethane cord has a much better elastic memory than injection molded O-rings because extrusion orients the long chain molecules in the direction of stretch. Molded O-rings are made with gear pumps that break the long chain molecules and inject them at random into the mold, so their molecules are fractured and not oriented in the direction of stretch. Consequently, our extruded belts are stronger and last longer than molded O-rings.

There are other reasons why molded O-rings are inferior. As molten urethane flows along two paths around the circular mold, it picks up contaminates like dust, air pollutants and mold release. It also cools slightly, and when the two paths come together, they form a knit line, the point where the two contaminated surfaces mesh. This point is weaker than the rest of the O-ring because contaminates tend to foil the bond and because the plastic is cooler -- not the optimum fusing temperature. This is the location where most injection molded O-rings break. The other break point is called the gate line, the point were molten plastic enters the mold. Turbulent flow caused by the sudden change in flow direction produces stress that weakens this point.

Moreover, injection molded O-rings require much more energy to bend. A mold by its very nature directs more urethane into the outside half of the belt circumference/diameter than to the inside circumference/diameter, so molded O-rings always fight to return to their original circular or oblong shape and do not easily conform to straight or serpentine belt paths. This is why back bending molded belts consumes excessive energy. Worse yet, belts on conveyor curves and line-shafts conveyors spiral like a candy cane, constantly turning themselves inside-out. Molded belts need a lot of energy to turn themselves inside-out because they have more urethane on the outside diameter than on the inside diameter, and they tend to scuff while doing that, so they often abrade. Extruded belts, on the other hand, have the same amount of urethane on both the outside and inside circumference/diameter, so they require much less energy to spiral and confirm easily to belt paths, even back bending paths.

Furthermore, molded O-rings have a tiny parting line bead running along the entire inside and outside circumference. This bead presents an obstacle to full surface contact with the roller or pulley groove, as well as requiring more energy to spiral, so it causes the belt to slip easier than smooth extruded round belts.

According to comments from one Motorized Drive Roller (MDR) manufacturer, the extra energy required to make molded O-rings bend and spiral is usually not constant, but rather comes in bursts that force their MDRs to experience constant high frequency amperage spikes that tend to damage the their motors and reduce their lifespan.

Back to top

Q26: It is rare, but sometimes round belts squeak. What causes it?

The squeak sound usually occurs when:

- The speed of the conveyor is very fast, and

- The slave rollers are relatively long (i.e., heavy) so they have a large angular moment of inertia, and

- There is no box covering all the rollers on the zone, so there is nothing to force all the rollers to stop at the same rate, and

- Without the momentum of a box on the MDR, the MDR stops very quickly, i.e. almost instantly -- like in a few tenths of a second.

The squeak is caused when the MDR forces the belts to stop too quickly, but the angular momentum of the slave rollers is so great that the rollers keep turning. Something has to give, so the belts are forced to slip a little on the slave rollers until the rollers stop turning. When belts with a high coefficient of friction slip, they squeak. The higher the angular momentum of the slave rollers, the more the belts will slip and squeak.

You can eliminate the squeak by:

- Ramping down the speed of the MDR so it does not stop so quickly. Itoh Denki's PLC allows you to do this. For example, instead of stopping in 0.2 seconds, set them to stop in 0.5 seconds. If you can program the empty zones to ramp down in speed, like in 1 second, but allow the zones carrying boxes to ramp down faster, then the speed of your conveyors will not be effected.

- Reducing the speed of your conveyor.

- Using lighter rollers that have a lower moment of inertia.

- Switching to belts that have a lower coefficient of friction, like rough green belts that slip without squeaking. However, they may also lower the driving force of the belts.

- Switching to thicker, ultra high tension belts that provide greater surface area contact with the rollers, like our .22" (5.6mm) 88A HEHT black belts. However, they are more expensive and more difficult to install because they are stretched 24%. They also require more energy to bend.

- Switching to flat belts that have a higher surface contact area, like our 1/32" thick x 1.38" wide (.8mm x 35mm) 83A flat belts. These will not slip on the rollers. However, they are more expensive and require more labor to install.

Theoretically, squeaks can also be caused at start up if the MDR is so powerful that it ramps up to high speed almost instantly, and there are no boxes on all the rollers to force them to all start at the same rate. However, we have not observed this to happen.

Back to top

Q27: Why do weld joints often protrude slightly in a small bump above the belt's surface?

Bump

Bump

When polyurethane belt cord is extruded, it is pulled out of a die and frozen in a water bath. This causes long chain molecules to be aligned in the direction of extrusion, which makes the belt very strong in the longitudinal direction.

When belts are welded, the heat changes the morphology of the plastic at the joint, making the molecules more randomly oriented there. Consequently, stretching the belt causes the joint to neck down more at that joint than the rest of the belt.

To offset this, we usually leave a little bump (e.g., about .010" or .2mm tall) at the joint, so when it necks down, it becomes flush with the rest of the belt. This does not make the joint weaker, but rather it becomes stronger.

If you prefer to have our weld joints flush with the belt surface, simply specify "grind welds flush".

Incidentally, you may know that steel welds behave differently because a bump at the weld joint makes it weaker. Steel, unlike polyurethane, is rigid so when tension is applied, the bump does not neck down, but rather focuses tension on the joint, making it prone to fracture. That does not happen with elastic polyurethane.

Back to top

Q28: How much should right angle diverter belts be stretched?

There are two types of right angle pop-up diverters, those that stretch the belts each time they pop up and those that don't. The latter will last longer because they don't have to stretch and relax frequently.

On those that don't stretch, the stretch is usually 10%.

On those that stretch, the stretch is usually 5% before pop-up and approximately 10% after pop-up.

Incidentally, the normal position of pop-up pulleys that stretches belts must be in the down position. If they are normally in the up position, then the belts will take a set and will not bounce back in the down position, so they will soon fall off the pulley.

Sometimes the problem is not the belt stretch, but rather the way the right angle diverter works. Such diverters work best when boxes are braked and come to a complete stop before being diverted 90 degrees. If boxes are not stopped ("diverted on the fly"), then their momentum can cause them to rotate and tip so a box edge dips below belts and lifts them off pulleys. In such cases the solution is to install fenders around the pulleys that force belts back on pulleys after they have been lifted off, as in the picture below.

.jpg)

Fenders on Right Angle Diverter Pulleys

You can purchase these fenders from Dematic.

Back to top

Q29: How to easily install high tension poly-v, HT, HEHT, V-Conform and Hytrel belts without tools.

Most of our customers do not use special tools to install high-tension poly-v, HT, HEHT, V-Conform, and Hytrel belts. They use the following procedure:

- Always wear eye protection and a safety helmet when installing high tension belts. Even though poly-v belts are only stretched a few percent, they pack a lot of energy. Ditto for HT, HEHT and V-Conform belts stretched high amounts. If a belt breaks or your grip on a loose roller slips, the belt and/or roller could become dangerous flying projectiles.

- Rollers used on line-shaft conveyors worked well when the shaft was spring loaded at the ungrooved end of the roller, so you could push in the shaft at the grooved end. However, they do not work well with high tension belts on Motor Driven Roller (MDR) conveyors.

- On MDR conveyors, make sure you order idler rollers with the shaft spring at the grooved end of the roller so you can push the shaft in from the ungrooved end of the roller. If in doubt, order springs on both ends of the roller shaft. They will cost slightly more, but you will be able to push the shaft in from both ends of the roller.

Roller Installer Tool

Roller Installer Tool

- If the spring is only located in the ungrooved end, you have to use a crowbar or this "make-it-yourself" Roller Installer Tool because it will be extremely difficult to install the roller by hand. With rollers on 2" or 50mm centers, this tool might not fit, so you might have to use a crowbar or winch.

- This video shows how to easily replace belts, when the spring is located in the grooved end of the roller. Following is a witted description on how to do it:

- Use the loose roller as a lever by inserting it through the belt that is already positioned around the adjacent installed roller.

- Make sure the belt's poly-v ribs fit into the appropriate grooves on both poly-v roller endcaps. HT, HEHT, V-Conform and Hytrel round belts must also fit in their roller grooves.

- Point that loose roller at an angle so its shaft is resting on the edge of the shaft hole in the frame closest to the belt. That shaft hole will become the fulcrum of the lever.

- Grab the other end of that loose roller and push or pull it (like you would a lever) stretching the belt until the shaft at the groove end pops into the frame. Now push in the other end of the shaft with a putty knife and guide the shaft so it pops into the hole in the opposite frame. The roller and belt are now installed. No special tools are needed.

- Never stretch a belt with a hook. Hooks will force the belt to bend sharply around a small diameter. This will damage the belt.

Back to top

Q30: How to size (choose the length) of ConveyXonic Poly-V belts.

To determine the ConveyXonic belt's size for different center distances, box weights and number of rollers per zone using your computer or cell phone, download Hutchinson's Belt Size Calculator by clicking here: Hutchinson's ConveyXonic Wizard.

If you want to understand the numbers on the ConveyXonic belts for all but a few ConveyXonic belt lengths, the numbers after the PJ represent the approximate outside circumference (OC) of the installed belt in millimeters, assuming a belt thickness of approximately 0.4mm. You can verify this with our Belt Sizer Length Calculator Method 3. First set the V-belt height at 0.4mm, the groove depths and percent stretch to zero. Then enter your pulley diameters and your center distance, and click on Calculate to get the Belt Cut Length, as in the following example. Now choose the closest PJ number to the Cut Length. That PJ number is the ConveyXonic poly-v belt length you should choose.

If the cut length and PJ size numbers are off by a few millimeters, remember that elastic ConveyXonic belts will work over a stretch range from 2% to 7%, so if you substitute values within the min/max center distances in our charts, you should be able to make the two lengths equal. That means you have found the correct size for your application. Here are links to our charts:

1.9" and 50mm rollers with 43mm pulley

2.5" and 63.5mm rollers with 60mm pulley

286.345, so round to PJ286

See Belt Sizer Length Calculator Method 3.

Since the belts can be stretched from approximately 2% to 7%, the circumference can vary by a few mm. This means that you will get the lowest driving force if your center distance is close to the minimum center distance shown in the these charts:

1.9" and 50mm rollers with 43mm pulley

2.5" and 63.5mm rollers with 60mm pulley

In that case, you may need to add an extra rib to the belt width if you want to move heavy loads.

For those few PJ numbers that are misnamed, Hutchinson cannot change their part numbers, so you must use the misnamed part number when ordering, but use the blue part number in the foot notes at the bottom of the above charts when calculating the circumference.

Dimensions for ribs on PJ-Section Poly-V Belts and Pulleys

Dimensions for PJ-Section Poly-V Belts and Pulleys

Back to top

Q31: How to make poly-v belts last longer and prevent premature failures.

Poly-v belts do not last long in acid, oil or greasy environments. If you are having a high number of failures due to abrasion, cracking or stripping along the belt length, and the problem is not the environment, then the cause may be inconsistent alignment and/or rubbing belts.

The drawing below shows what we mean by "consistent and inconsistent alignment".

Both belts on both roller endcaps need to be exactly parallel to each other, but must not touch. In other words, belts must be consistently aligned and not rub against each other. If they rub against each other, it will cause fraying at the edges. Inconsistently aligned belts and/or rubbing belts will likely fail prematurely.

Misaligned Poly-V Belts may cause Premature Failure

Poly-v belts inconsistent alignment Other possible causes of premature failures include belts rubbing against boxes, pallets or conveyor parts like finger guards or cross-supports. Moreover, belts can slip, overheat and abrade if rollers are forced to keep turning under heavy boxes or pallets that cannot move due to jams or accumulations. In such cases, sensors should be used to detect stoppages and turn off motors before belts begin to slip within 4 seconds after a stoppage has been detected.

Note: The number of starts and stops at very fast acceleration/deceleration combined with high motor torque can influence the durability of poly-v belts. Therefore, Hutchinson recommends no more than 1 million starts and stops per year. Based on 18 hrs/day and 6 days/week usage, this translates to a maximum of 3 starts/stops per minute. You can minimize this problem by accelerating/decelerating at a slower rate, using PLCs that allow you to ramp up/down in speed.

Back to top

Q32: What is the shortest Hytrel belt that can be used on 1.9" (48.3mm) conveyor rollers?

Answer: 9.79" (249mm). Hytrel belts are used primarily for very low temperature or harsh chemical applications. During installation, they must not be over stretched because polyester, unlike urethane, will not bounce back after being stretched. Unfortunately, when the rollers are closest (touching each other), you cannot put the belt in the groove of the second roller without first stretching it over the 1.9" section of the second roller as in the drawing below. This means that the shortest 3/16" (5mm) belt that can be installed without stretching the belt is 9.79" (249mm) cut length, and the shortest center distance between 1.9" rollers is 2.60" (66mm), assuming a minimum of 8% stretch. When the tolerance range on cut length is included, the minimum belt length should be 9.94" (252mm).

Shortest Hytrel belt = 9.79" (249mm) cut length

If you need 2" (50mm) center distance between 1.9" (48.3mm) conveyor rollers at low temperatures down to 15°F (-9°C), then you need to use poly-v belts.

Back to top

Q33: Can we weld, join or splice Dura-Belt's thermoplastic belts ourselves (Do it yourself)?

Dura-Belt provides hot plate splicing kits and tools plus belt splicing (welding) instructions so that anyone can weld its round, vee, and flat thermoplastic belting. However, our Super Strong Welding process makes welds up to twelve times stronger than you can get with vibrational friction welding tools or hot plat welding tools.

Warning: Always weld in a well ventilated area because hot urethane fumes (especially smoky fumes) are poisonous. Heated urethane decomposes into small amounts of hydrogen cyanide, the death chamber gas, so do not breathe fumes or let them get in your eyes.

Furthermore, you can join our hollow belting without tools by merely inserting an aluminum barb in the tube ends. However, the maximum stretch is only 7% because greater stretch will pull the barbs out of the belts. Therefore hollow tubing cannot be used in high tension applications, and minimum pulley diameters are greater than those for welded belts.

Warning: Eye protection must be worn around hollow belts because if a barb pulls out, the belt can strike a person like a bullwhip, and the sharp barbs can cut and injure eyes.

Consequently, it is usually more cost effective, time saving and safer to purchase belts already made endless by Dura-Belt -- unless you need to weave belts through a machine in order to join them.

Back to top

Q34: Can Dura-Belt's stretchy, elastic urethane or Hytrel be used on slider beds (sliderbeds)?

Urethane and Hytrel have a high coefficient of friction (COF), so friction generated when they move heavy loads over metal or UHMW plastic slider beds may cause urethane and Hytrel to abrade and/or overheat, stretch and lose their elastic memory. This problem becomes worse as the load becomes heavier, the speed becomes faster and/or the length on the slider bed becomes longer. With round or v-belts the problem can be minimized by reducing the surface contact between the belt and sliderbed. For example, make the groove wider so it does not pinch the belt and/or use rough green or blue 88A/90A urethane belts because they have a lower COF due to less surface contact and harder durometer. With flat belts you should use multiply belts with nylon fabric on the bottom. Nylon has a low COF, so it resists abrasion when riding on slider beds.

This rule does not apply if the load is very light and moving slowly like berry baskets and produce containers.

Another exception is where urethane and Hytrel can be used on slider beds made from aluminum topped with Teflon tape. Teflon's low .05 COF reduces friction heating so low that round belts often work well, especially because aluminum conducts away any heat generated by friction. Teflon tape can also be used on steel slider beds (if you mistakenly built a system that uses slider beds with urethane or Hytrel belts), but the belts probably will not last as long as they would with aluminum beds. In conclusion, urethane and Hytrel belts work great on roller conveyors and pulleys, but not on some slider beds.

Back to top

Q35: How long do Twisted belts (Zero-downtime quick-connect belts) last?

The picture below shows two "white frosted" belts that were cut after they wore out. Those belts were either slipping on their rollers/pulleys or rubbing against something like the frame's cross-support. When that happens, the belt's surface abrades causing that white frosty look. In addition, the rubbing friction causes the belt to overheat and elongate, which leads to premature belt failure.

Three Worn Twisted Belts with Plastic Hooks and one New One

The nice thing about the frosted white color is that you can easily see when a belt is distressed and take action to eliminate the problem before the belt fails.

That yellow colored belt that broke at the loop shows exactly how twisted belts usually fail. It's normal and ultimately unavoidable because the loop is the thinnest part of the belt, and friction between the hook and the loop eventually cuts through the belt loop. That yellow color means the belt was working for a significantly long time before it failed because urethane slowly gets yellower over time.

These are twisted 3/16" thick belts, but the end loops are only 1/8" thick, so the pressure on the loop strand is tremendous -- it's the weakest point on the belt. Friction between the hook and that thin loop ultimately causes the hook to cut through the loop, but crimped steel hooks or pinching/self-lubricating plastic hooks make belts last somewhat longer because they reduce or minimize that friction.

That is why we say: "Twisted belts cost twice as much as endless belts and last half as long, but they virtually eliminate downtime." That's why users buy them.

They were initially designed to act as stopgaps until the plant is shut down for vacation when round belts are replaced, but some users use them in place of round belts because they are so easy to install, especially with our Speedy Belt Installer.

The clear colored belt is new and unused.

Back to top

Q36: Thermoplastic urethane belts are NOT precision belts. How are they made? Design tips.

Thermoplastic urethane raw material pellets are manufactured by giant companies like BASF, Dow, Covestro, and Lubrizol. The pellets are melted in an extruder and forced through a die to produce the cord that Dura-Belt splices to make belts with its Super-Strong Weld joints.

Urethane belts have wide tolerance ranges. They are NOT precision belts because thermoplastic urethane is made only in large vats (It's a batch process, not a continuous process), so the properties of the pellets vary with each vat. The giant manufacturers will not let us specify the properties we want, so we have no choice but to take what they produce. This means that the output from each vat can vary slightly as follows:

- Shore A Durometer (hardness) can vary by +/-5 (Covestro says +/-3, but the others say +/-5)

- Modulus of Elasticity can vary by +/-10%

- Viscosity (Melt Flow Index) can vary, e.g., by 2 to 10 grams/10 minutes

- Color can vary in these shades: water clear, milky white, tan, golden yellow or amber. Even though we use the term "clear color", the correct color designation used by urethane manufacturers is "natural color", and it can be any of those previously mention shades of "clear".

- Surface Texture can vary slightly from smooth to fine matte to chalky white. The latter is called "bloom". It occurs on ester-based urethane when small amounts of oligomers slowly migrate over time (e.g. a few months) to the belt's surface. Bloom can be easily rubbed off with your fingers, rubbing alcohol or hot water and does not effect the belt's performance or its rating as food grade. Urethane is made from long chain polymers. Oligomers are short chain polymers that are a by-product of long chain polymerization.

In addition, when urethane is extruded:

- Thickness can vary by +/-0.005" (+/-0.13mm) or +/-3% whichever is larger.

- Ovality (roundness) can vary by up to 3% for most cords.

- Since thickness and ovality varies, each strand of cord stretches by slightly different amounts when pulled straight and cut. This is why the length of long belts can vary by up to +/-1%, a fairly wide tolerance range. Short belts with cut lengths less than 12.5" (318mm) can vary by up to +/-1/8" (+/-3mm), alternately +0/-1/4" (+0/-6.3mm).

Because of all the possible variations, we recommend that belt designers should factor in a large safety factor -- preferably 2 to 3 times the desired strength. Ideally this means that if it takes 1 lb. of force to move your load, you should design belts to provide 2 lbs. or 3 lbs. of force. If you can do that, your belts will last longest, but if that is not possible, belt life may be reduced. Therefore, design your equipment so belts can be easily replaced.

Back to top

Q37: Why does RPM decline (roller speed slow down) with each slaved roller? -- Creeping vs. Slipping belts

Elastic belts (including ConveyXonic poly-v belts) don't normally slip. Instead, all elastic belts will creep as they go around the tight side to the limp side of a pulley/roller. This causes a slight reduction in RPM with each slave roller, usually 0.5% to 1.5%. In other words, if the motor is running at 100 RPM, and the creep is 1%, then the first slave roller will rotate at 99 RPM, the second slave at 98.01 RPM, the third slave at 97.03, etc.

Therefore, the more slave rollers on one side of a motor, the greater the reduction in RPM with the last slave, so with 10 slaves the RPM of the last slave is approximately 90.4 RPM. That is why the Motorized Drive Roller (MDR) should be located in the middle of a zone and not on the end. If it is in the middle, there will only be 4 slaves on one side and 5 slaves on the other side of the MDR. This will minimize creep.

Note that 'creep" is the reason that most zones contain a maximum of 10 rollers. Although if you can live with a greater reduction in speed at the end of zones, we have customers that are using our .216" HEHT black belts on zones of 15 rollers moving 100 lb tires. One customer is even using them on 19 roller zones.

HEHT black belts move 100 lbs on 15 roller zones

You can virtually eliminate creep by making pseudo MDRs at the end of zones by using 2 narrow flat belts. You can also make pseudo MDRs by using two long round belts, but all rollers must have 4 grooves.

Back to top

Q38: How to install Poly-V and Poly-O endcaps on each end of a conveyor roller.

Some applications require our Poly-V or Poly-O endcaps to be inserted on each end of a conveyor roller. While the installation of the first endcap is easy, the second endcap initially extends out longer than the shaft, so aligning the hex shaped shaft with the endcap's hex inserts may appear to be extremely difficult. This tool solves that problem.

Poly-v and Poly-O endcap assembly tool

for endcaps at both ends of conveyor rollers

Back to top

Q39: How to clean urethane belts. "Dirty belts" are a positive attribute.

Urethane is slightly static attractive, so it will attract a thin layer of dust that will color urethane belts brown, black or reddish, depending upon the color of dust in your location. Aluminum rollers and pulleys will also turn belts black because that is the color of aluminum oxide. However, none of these things should significantly effect belts' performance, so why clean them? Unless oil or grease gets on belts, or they are in a washdown environment, no one that we know cleans them.

However if you need to clean them, we do not recommend soapy water because soapy residue may cause belts to slip. Therefore, we recommend cleaning belts with rubbing alcohol or acetone. Acetone (the key ingredient in nail polish remover) is flammable, and you should wear gloves, so use it with caution. Acetone also attacks urethane, but very slowly, and it evaporates so quickly that it doesn't seem to harm the belts. It is especially good for removing oil or grease.

Actually, "dirty belts" are a positive attribute. If a belt is dirty, you know it is not abrading and/or slipping. If it abrades or slips a lot, it will turn whitish in color because abrasion rubs off the dust, and the rough surfaces makes even colored belts look white. This means your maintenance department can quickly spot a injured belt and focus on eliminating the cause. Therefore, we do not recommend cleaning the belts unless oil or grease gets on them, or they are in a washdown environment.

Back to top

Q40: What causes "shortages" (under-counts) and "overages" (over-counts) in bunches or plastic bags?

We often package belts in wire-tied bunches or plastic bags of 50, 100 or more pieces. We weigh count bunches and plastic bags because humans often do not count accurately. They make mistakes. Moreover, counting them with humans would take too much time and force us to increase prices.

Urethane belts are not precision belts because they have fairly large length, width, and durometer (correlates to specific gravity) tolerances that make exact counts impossible. See Belt Tolerances.

Weight counts can be inaccurate if the sample size is small, like only 25 belts, but we sample count 150 belts for 100 piece bunches so our weigh counts should be very accurate.

Nevertheless, the size and number of tolerances mean the actually quantity in a wire-tied bunch or bag will vary in a normal (Gaussian) distribution, so if a bunch of belts looks like there should be 100 belts, sometime there will be fewer belts, e.g., 97, 98, 99 belts, and sometimes there will be more belts. e.g., 101, 102, 103 belts.

Normal (Gaussian) distribution

If your production department does not understand this, they will often report under-counts (shortages), but production departments virtually never report over-counts (overages), so you cannot rely on their inputs. (We can say this with certainty because we have tested it by purposely including extra belts in some bunches or bags, and then asking customers how may overages did their production department report. So far, no customer has ever reported over-counts.) Therefore, please inform your production department that not every bunch or bag will be exactly 100 pieces due to weigh counting.

If you think our counts may be systematically short, then you need to recount them using statistically valid sample sizes. The following link will tell you how many bunches to sample https://www.qualtrics.com/experience-management/research/determine-sample-size/

Make sure you randomly select samples from the whole distribution. Also you must weight count them because humans make mistakes when they count. Then report the details to us. If there are more underages than overages, we will replace the difference and ship them to you at our expense.